Bolt Holes

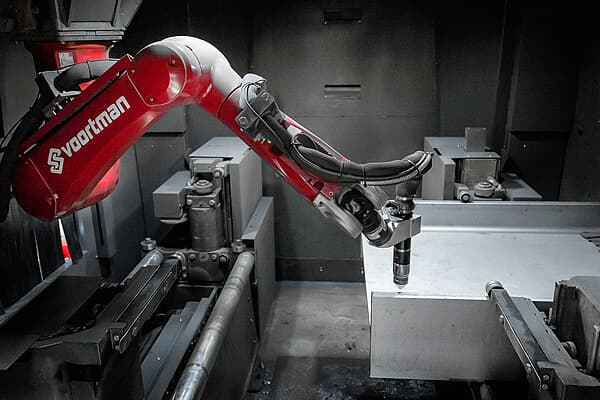

Rat holes, seismic connection (jay�allan or dog bone connections), copes in the lead and trail ends of a product. Block outs, holes of any shape or size, weld preps, markings on all four sides and much more. VoortmanV808 can work on all four sides using only one robot. It is the most versatile machine currently available. All profiles and cuts can be made without any programming required.

Voortman V808 robotic heat cutting machine is equipped the Panasonic TL-1800G3 coping system. It's faster and more versatile than ever. The robot's torch-nozzle is equipped with an accurate measuring sensor. The machine parameters automatically compensate the differences between the theoretical and actual dimensions to ensure the highest quality product. To speed up the process, the coping robotic only measures the sides that will be used.